Why PULL

The systemic problem in supply chains today is that all key activities of what to make, buy, and how much to stock are based on last century's methods of forecast and PUSH. The inherent errors in forecasts set up a chain of cause-and-effect conditions that results in whiplashes of order quantities, expedites, stock-outs, overstocks, and capacity problems. All of which you pay for either by constantly managing exceptions, or it blocks you from achieving the next level of performance.

Attempts to align business processes, open views to each other’s data, and use sophisticated software have produced mixed results. At the end of the day, the solutions still rely on a forecast, and a forecast always has errors.

PULL solves the problem from a completely different direction. Actual demand is 100% accurate. When aggregated correctly and used in combination with strategically placed inventory and capacities, quantities are automatically pulled through the supply chain to where sales are occurring. The resulting speed and smoothness dramatically increase supply chain performance.

PULL also takes min/max inventory operations to the next level.

When PULL Replaces PUSH: Proven Results

The results summarized below are from clients I have helped go from PUSH to PULL. While these projects varied greatly in scope and product, each of them were completed in about 3 months and delivered near-immediate results. The Military organization used a forecast every 4-6 months to determine min/max inventory levels. The other two companies used a monthly forecast process. The cut & sew company had made significant investments in the prior 5 years to improve forecast accuracy.

Cut and Sew Products from Asia Suppliers

- 50% reduction in manufacturing lead-times

- 40% percent reduction in total inventory at wholesaler and manufacturing

- $400K per year expense reduction

- 30% increase in capacity

- Significantly less effort to manage

PVC Building Products for Regional Wholesalers and Big Box Retailers

- 100% on-time delivery up from 85%

- 10% reduction in inventory

- 50% reduction in manufacturing lead-times

- Eliminated expedites

- Eliminated overtime (skilled workers were quitting due to constant forced overtime)

- Substantial increase in net profit

Military Helicopter Repair and Overhaul

- 50-80% reduction in repair and overhaul lead-times

- Less inventory

- Eliminated overtime

- Expedites reduced from 40-50 % to less than 10%

- Follow up Lean projects where highly focused to continue improvements

Working Together

PULL is a business process solution instead of being software centric. This makes it fast to implement and for significantly less money.

We work together to re-engineer your business processes for inventory purchases, inventory management, capacity planning, and their integration with sales, distribution, and product lifecycle. Sometimes, we may need to revise the flow through manufacturing if capacity is still an issue once overproduction and whiplash are minimized. Monitoring and managing PULL based processes will require some new or revised reports, but in most cases, these are accomplished using your existing IT investment.

For Implementations

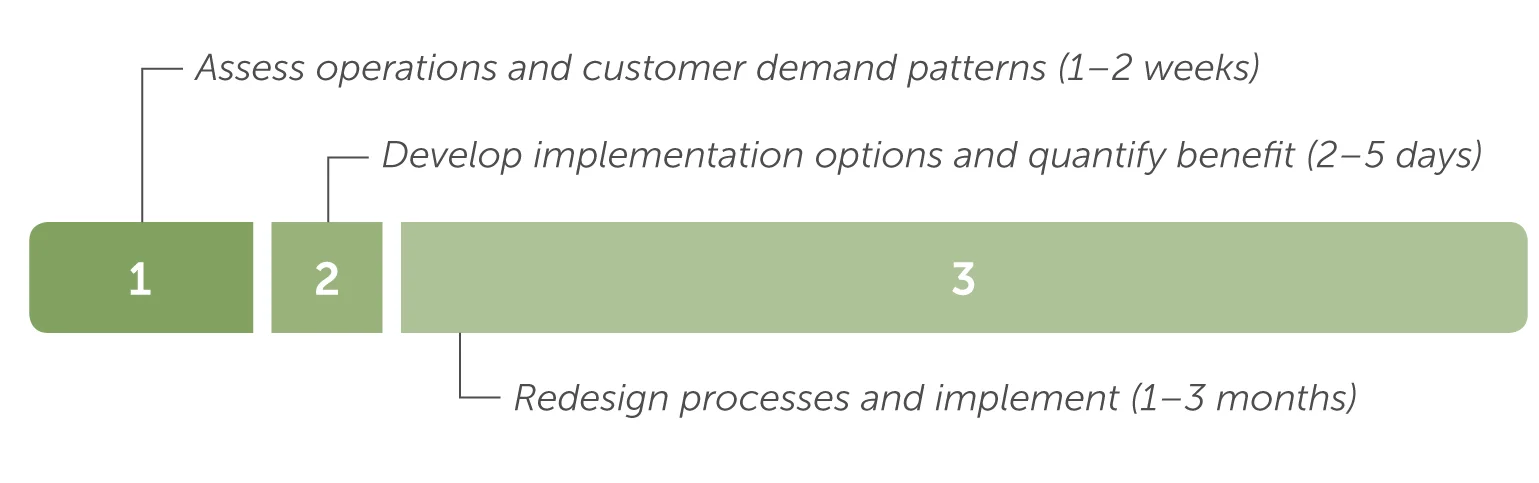

We work in three phases to keep you in control with simple go and no-go decisions. Durations vary depending on scope but typically take 2–4 months. Our clients usually see direct payback within the first 6 months.

We've successfully implemented PULL methods for single product lines to show benefits, or worked in stages with multiple 2-4 month engagements to implement across an entire enterprise.

For Analysis Only Projects

Benefits can be analyzed up front and are an excellent way to test the value and fit before committing to an implementation. An analysis usually takes 1-3 weeks depending on the numbers of SKUs and operations involved.

Contact Bruce Watson

Solid assurance it's done right, quickly, and it increases your supply chain ROI

I have 10 years experience teaching and guiding leaders in companies such as Nike, Delta Air Lines, and the US Marines to implement PULL based processes. I specialize in three areas:

Increasing sales and lowering supply chain costs by synchronizing manufacturing capacities, materials, parts and finished product inventories to actual demand.

Reducing lead times and opening capacity by increasing the flow through existing manufacturing processes.

Identifying and prioritizing the vital products and improvement projects that will have the most impact on profit and reliability.

I am not a PhD or sales person. I am an experienced practitioner that works side-by-side with you to make real operational improvement. Accomplishments include:

Increasing part and product availability to 100% with 20-40% less inventory

Decreasing supplier lead times by 60-80%

Reducing manufacturing and repair lead times by 25-75% as well as eliminating overtime.

Start the Conversation

Call us at +1 (503) 318-2832 or use the form below.